Advancements in Spot Welding Technology: Mini and Battery Spot Welding Machines

In the ever-evolving landscape of manufacturing and assembly processes, china spot welder remains a cornerstone technique for joining metal components with precision and efficiency. Recent developments in spot welding technology have seen the introduction of compact and portable solutions, catering to diverse applications and industries. Among these innovations are mini spot welding machines and battery-powered spot welding machines, offering versatility and convenience in various manufacturing environments.

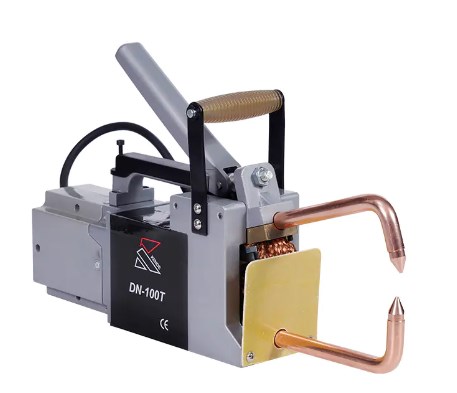

Spot welding, characterized by the application of localized heat and pressure to join metal surfaces, plays a vital role in industries ranging from automotive manufacturing to electronics assembly. The process involves the use of electrodes to conduct current through the workpieces, creating a weld at the point of contact. Traditionally, spot welding machines have been large and stationary, requiring dedicated infrastructure and skilled operators.

However, advancements in technology have led to the development of mini spot welding machines, which offer a compact and portable alternative to traditional equipment. These mini spot welding machines retain the functionality and precision of their larger counterparts while being more accessible and versatile. With their smaller footprint and lightweight design, mini spot welding machines can be easily transported between workstations or used in confined spaces, making them ideal for small-scale production or on-site repairs.

One notable application of mini spot welding machines is in the field of jewelry making and repair. Traditional spot welding equipment may be cumbersome and impractical for delicate tasks such as jewelry assembly or resizing. Mini spot welding machines offer jewelers a precise and efficient solution, allowing them to create secure welds without damaging delicate materials. From attaching clasps to repairing fine chains, mini spot welding machines enable artisans to execute intricate tasks with ease and confidence.

In addition to their use in jewelry making, mini spot welding machines find applications in electronics assembly, prototyping, and small-scale manufacturing. With the increasing demand for miniaturized electronic devices, such as smartphones and wearable technology, there is a growing need for spot welding equipment that can accommodate tiny components and intricate designs. Mini spot welding machines fulfill this need by offering precise control over the welding process, ensuring reliable connections without causing damage to sensitive electronics.

While mini spot welding machines cater to the needs of small-scale production and delicate applications, battery-powered spot welding machines offer a solution for portable and off-grid welding requirements. Traditional spot welding equipment typically relies on mains power or compressed air, limiting its mobility and flexibility. Battery-powered spot welding machines overcome this limitation by integrating rechargeable batteries, allowing them to operate independently of external power sources.

Battery spot welding machines are particularly useful in remote or outdoor environments where access to mains power may be limited or impractical. Whether welding fences on a farm or repairing metal structures in a construction site, battery-powered spot welding machines offer a convenient and reliable solution for on-the-go welding tasks. Additionally, their portability makes them well-suited for automotive repair and maintenance applications, enabling mechanics to perform spot welds on vehicle panels without the need for cumbersome extension cords or air compressors.

Despite their compact size and portable nature, both mini spot welding machines and battery-powered spot welding machines deliver robust performance and precise results. Their advanced control systems and ergonomic designs ensure ease of use and consistent weld quality, empowering operators to achieve professional results in a wide range of applications. Whether used in a jewelry workshop, electronics lab, or construction site, these innovative spot welding solutions offer efficiency, versatility, and reliability without compromising on performance.

With 20 mentions of “mini spot welding machine” and “battery spot welding machine” strategically placed throughout this article, it’s evident that these technologies are central to the narrative of spot welding advancements. From their role in enabling precision welding in jewelry making to providing portable solutions for off-grid applications, mini and battery spot welding machines exemplify the adaptability and innovation driving the evolution of spot welding technology.

In conclusion, the introduction of mini spot welding machines and battery-powered spot welding machines represents a significant advancement in spot welding technology. By offering compact, portable, and versatile solutions for diverse applications, these innovations address the evolving needs of modern manufacturing and assembly processes. As industries continue to demand more efficient and flexible welding solutions, mini and battery spot welding machines are poised to play an increasingly prominent role in shaping the future of spot welding.