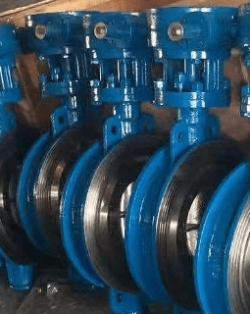

Ball valve supplier in Dubai

UAE Valves is the greatest Ball valve supplier in Dubai. Its scope covers various sorts of industries such as the oil and gas and chemical processing industries. The goods provided are all reliable for making sure your systems have no faults.

The ball valve is a type of valve that controls fluid passage by the hollow spherical ball. A ball valve is open when the hole will align it with the pipeline such that fluid will pass through. When a ball valve is closed, the ball rotates 90 degrees to fully cut off flow. Among other valves, the ball valve is highly cherished by users for its tight seal and good control with minimal maintenance. They are particularly suited to those applications where high pressure or quick shut off is needed.

Types of Ball Valves:

1. Double Block and Bleed Ball Valve: In this ball valve type, there are two seating surfaces that isolate the fluid flow from both the upstream and downstream sides. Moreover, a bleed valve vents out the fluid that might be held between the seats. Most applications for these valves show up in critical applications that are mostly in the oil and gas industry, where both safety and leak-prevention are absolutely essential.

2. Welding Ball Valve: Welding ball valves are used welded into piping system thus suitable for applications where long term performance without leakage is desired. They are also abundantly used in high pressure and high temperature services, as seen in oil and gas pipeline service.

3. Top Entry Ball Valve : With top entry ball valve configuration, the components of a valve can be reached top-serviced, directly, without removing it from the pipeline. For many maintenance-demanding applications or places of valves installation that may present access difficulties, these configurations are widely used.

4. Trunnion Ball Valve: This is the trunnion ball valve where two trunnions help mount the ball. This ball valve is stable and can handle bigger high-pressure systems better. The trunnion ball valve is rather well suited for heavy-duty applications in oil and gas, among other things, where large fluid quantities have to be safely and efficiently handled.

5. Jacketed Ball Valve: Jacketed ball valves are those valves whose body is covered with a layer to allow heating or cooling fluids to pass through for maintaining the fluid temperature that passes through the valve.

6. Float Ball Valve A float ball valve is a floating ball that floats between two seats. In the closed position, the floating ball is pushed against the seat on the downstream side. This closes the valve very tightly. They are used in applications that are moderately pressurized where the valves must be reliable but not so heavy-duty as trunnion ball valves.

7. Forged Steel Ball Valve : This ball valve is made of forged steel, which gives much strength and durability to its application at high pressure. These types of valves are mainly used in critical applications, including oil and gas, power generation, and chemical processing.

Ball Valve vs. Gate Valve

The main difference between ball valves and gate valves is in their design and the way they function. A gate valve has a wedge-shaped gate to close or open the flow, taking a little longer to either close or open and maybe experiencing wear over time. They are often used for full-open or full-closed positions but not quite efficient for throttling control.

On the other hand, a ball valve provides for quick, one-quarter turn actuation and can provide for on-off control with close shut-off and almost negligible leakage. Ball valves are often used in situations requiring faster turn-off or high-cycling operation. It is even more secure than gate valves for use at higher pressure systems. In many industries, therefore, it is a much more versatile piece of equipment.

The operation of a floating ball valve is based on the principle where the ball “floats” freely between two seats. When closed, the ball is forced up against the downstream seat in order to make a seal. Floating ball valves can thus be applied to applications of moderate pressure; they find great use in water treatment, HVAC and oil and gas industries wherein quick shut-off and assured performance are paramount. Floating ball valves are generally smaller and lighter than trunnion ball valves, making them an excellent option for systems with lower pressures or where space is a concern.

Why Choose a Ball Valve?

Ball valves are suitable for numerous applications due to their reliability, ease of use, and the ability to handle high-pressure and high-temperature systems. They offer quick operation through a simple quarter turn, making them ideal for processes requiring fast shutoff or very precise flow control. They also ensure tight sealing, which reduces leaks and enhances safety in the system.

In conclusion, ball valves are an effective, strong, and flexible solution within the control of flow across various industrial areas. They can be applied in the oil and gas pipeline networks, chemical processing plants, and HVAC systems to ensure high performance and reliability in operation. As one of the ball valve suppliers in Dubai, ensures wide range ball valves to fit into various industrial needs for that high-quality reliable product with any application.

Which industries use Ball Valve?

Ball valves are essential in many industries due to their durability, reliability, and efficient flow control. They are commonly used in:

Oil and Gas: For controlling the flow of crude oil and gas in pipelines and production systems.

Chemical Processing: To manage hazardous chemicals and fluids safely and effectively.

Water and Wastewater Treatment: For regulating water flow and preventing backflow in treatment facilities.

Power Generation: In steam, water, and gas systems for flow regulation and shutoff.

HVAC Systems: To regulate the flow of air and water in heating, ventilation, and air conditioning systems.

Marine Industry: For fuel, water, and waste management on ships.

Automotive: In fuel, coolant, and air conditioning systems.

Mining: To manage water, slurry, and chemicals in mining operations.

Pulp and Paper: For controlling the flow of chemicals, water, and slurries in production.

With their quick shutoff and tight sealing, ball valves are trusted in these industries for their performance and reliability.UAE Valves is a leading Ball valve supplier in Dubai, offering solutions across various sectors.

Description:Available materials: Cast iron, WCB, WCC, WC6, LCC, LCB, Titanium, SS304, SS316, CF8, CF8M, F55, F51, F53, Monel, Ductile Iron.PN- PN10 to PN450Class: 150-2500Size: 1/2”- 48”.Operations: Lever operated ball valve, electric actuated ball valve, pneumatic actuated ball valve, gear operated ball valveEnds: Flanged, Butt weld, Socket weld, Threaded.

Visit us: https://www.uaevalves.com/product-category/ball-valve/