Precision and Consistency Redefined: Cap Molds for Dice Set New Standards

In the world of tabletop gaming, precision and consistency are crucial elements that can greatly enhance the gaming experience. One essential element in achieving this is the use of high-quality cap molds for dice production. The cap mould company plays a pivotal role in ensuring that each dice is greatly shaped and possesses accurate weight distribution. In this article, we will delve into the functionality and significance of cap for dice and explore how they contribute to creating a great gaming experience.

Functionality of Cap Molds for Dice:

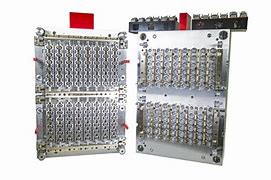

Cap molds for dice are specifically designed to produce intricate dice shapes with utimportant precision. These molds feature carefully engineered cavities and imprints that are critical in shaping the dice with consistent symmetry across all sides. By using advanced computer software and cutting-edge machining techniques, cap molds can achieve the desired intricacy and precision in manufacturing various types of dice, including standard six-sided dice, specialized role-playing game (RPG) dice, and custom-designed dice.

Accurate Weight Distribution:

One of the key functionalities of cap molds is their ability to ensure accurate weight distribution in dice. Each side of a dice should have an equal chance of landing face-up when rolled. molds achieve this by carefully determining the depth and shape of each cavity, allowing for consistent weight distribution throughout the entire dice This uniformity ensures fair gameplay and prevents any bias that could arise from unevenly weighted dice.

Repeatable Precision:

Cap molds are celebrated for their ability to produce identical dice with repeatable precision. This is especially crucial in games where identical dice are used for randomization, such as gambling or various board games. The precise dimensions and consistent shaping provided by cap molds ensure that each dice produced is an exact replica of the previous one. Players can rely on this consistency for accurate results, enhancing the fairness and integrity of the game.

Quality and Durability:

Cap molds are typically constructed using high-quality materials, such as stainless steel, aluminum, or brass. These materials are chosen for their durability and resistance to wear and. By utilizing sturdy materials, cap molds can withstand long production runs without compromising the quality of the dice produced. This that gamers can enjoy their favorite games for an extended period without the need for frequent mold replacements or repairs.

Cost Efficiency:

Cap molds for dice offer a cost-efficient solution for game manufacturers and dice producers. By utilizing the precision and consistency provided by cap molds, manufacturers can significantly reduce production costs. The ability to quickly and accurately produce large quantities of dice allows for economies of scale, making it more cost-effective than manual molding methods. This cost efficiency can be passed on to consumers, making gaming more accessible to a wider audience.

Versatility in Design:

Cap molds empower game manufacturers and designers with endless creative possibilities. With the ability to produce complex and intricate dice designs, cap molds facilitate the creation of visually appealing and important dice sets. Whether it’s incorporating different patterns, symbols, or textures, cap molds allow for excellent customization options. This versatility in design allows creators to enhance the overall aesthetic experience and captivate players’ imaginations.

Innovation and Advancements:

The continuous advancements in cap mold technology have revolutionized the dice manufacturing industry. From traditional manual molding techniques to the utilization of computer-aided design (CAD) software and computer numerical control (CNC) machining, the evolution of cap molds has significantly improved production efficiency and accuracy. These innovations have propelled the industry forward, creating a new standard for precision and consistency in dice manufacturing.

Conclusion:

Cap molds for dice hold remarkable significance in the gaming industry, providing the foundation for precise and consistent dice production. Through their functionality in ensuring accurate weight distribution, repeatable precision, and versatility in design, cap molds contribute to creating an immersive gaming experience. As technology continues to advance, we can expect further enhancements to these molds, continuously raising the bar for precision and quality in the world of gaming.